Prof. Bivas Saha with his team member featured holding a ceramic paver coated with the radiative cooling paint at JNCASR (an autonomous institution under Department of Science & Technology, Govt. of India.)

The International Energy Agency has found that the use of air conditioners and electric fans to keep buildings cool amounts to almost 20% of the total electricity consumed in buildings globally. Furthermore, in areas affected by the “heat island” effect—wherein temperatures rise in places with abundant concrete and a lack of green spaces—it is impossible to rely on energy-based cooling solutions, such as air conditioners, because these only exacerbate this effect. These cooling solutions are also harmful to both public health as well as the environment in the long run, and contribute massively to the climate crisis. This highlights the need for a practical solution that does not require the use of air conditioning or water cooling.

Prof. Bivas Saha, Associate Professor at the International Centre for Materials Science, Chemistry and Physics of Materials Unit, and School of Advanced Materials, at JNCASR, decided to contribute to efforts of finding such a solution. Through rigorous research, his team and he recently developed an affordable, radiative cooling paint that can make a difference. This development has been detailed in a paper published in Wiley’s Advanced Material Technologies.

How can just a coating of paint possibly solve the mammoth problem of rising energy expenditure? The answer lies in the unique molecular structure of the paint itself.

“When visiting a temple, we leave our footwear outside the temple and walk with our bare feet. In that moment, we really understand the immediate implication of overheating.” explains Prof. Saha with a smile.

Overheating of material surfaces can cause circuits and machinery to malfunction, and researchers are constantly working towards finding methods to help cool them and maintain their temperature. Prof. Saha’s team are part of this community of researchers and they primarily work on heterostructures and materials with a focus on optical and electrical properties, particularly heating and cooling.

In this case, they deviated from this primary focus and sought to address the issue of buildings and surfaces heating up due to solar radiation, particularly in areas with high temperatures, like northern India. The goal was to create a paint that could be integrated with ceramics or cement to provide a cost-effective and environment-friendly solution for cooling buildings. What began as a specific solution-finding endeavour for a collaborator and funder of JNCASR, the Ras-Al Khaimah Center for Advanced Materials near Dubai, evolved into the development of a material with potential cooling ability and numerous applications in the current climate crisis scenario.

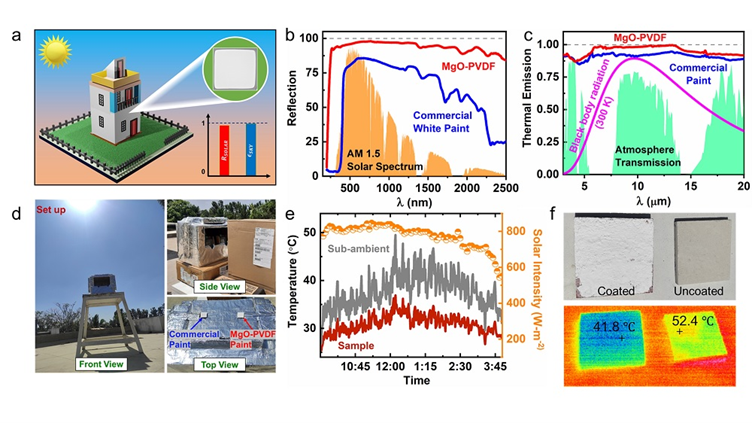

While some existing materials can provide cooling of up to 2–3°C, Prof. Saha’s team had an ambitious target of achieving a cooling effect of greater than 10°C. They first examined how solar radiation caused heating and then designed materials that did not absorb the radiation. They also explored a combination of different materials to achieve both solar light reflection and emission within the atmospheric transmission window. They finally used magnesium oxide (MgO)-polyvinylidene fluoride (PVDF) nanoparticles prepared from materials that are abundant, cheap, non-toxic, and non-harmful to create a polymer nanocomposite paint.

“I would call these nanocomposites as metamaterials. They are superhero materials that can go beyond what normal materials can do.” says Prof. Saha.

Their paint demonstrated excellent cooling performance under hot sunlight. It could bring about a temperature decrease of more than 10°C, almost double that shown by conventional white paints. Therefore, it is a potential cost-effective and environment-friendly solution for cooling buildings. Additionally, it is water-resistant and can be easily coated on pavers, wood sticks, and other surfaces with high uniformity and good adhesion.

(a) A schematic of a building with radiative cooling paint. (b) The MgO-PVDF coating reflection spectra compared to that of a commercial white paint, along with the AM 1.5 solar spectrum. (c) Thermal emission spectra of MgO-PVDF coating, commercial paint, blackbody (BB) spectrum at 300 K, and atmospheric transmission profile. (d) A photo from a field text where radiative cooling measurement setup was employed on a flat roof in Bangalore, India. (e) Real-time outdoor cooling results of the MgO-PVDF coating with respect to sub-ambient conditions. (f) Photograph and thermal image of a coated and an uncoated ceramic paver placed outdoors.

This development can benefit areas where the heat island effect contributes to increased temperatures, such as cities in the equatorial regions, southeast Asia, Africa, and the Middle East. The cooling effect of the paint can potentially have a positive impact on energy consumption and human health. This research is currently open to various industry partners for potential scale-up opportunities.

This research success story was published by the Department of Science and Technology through the Press Information Bureau. The research story was then picked up by The Hindu, Daily Pioneer, Paint Square, Mysuru Infra Hub, and more.